Large CAD Assemblies

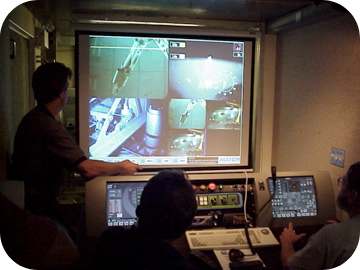

Quest ROV (Remote Operated Vehicle) & Control Console

Lead Integrations Designer

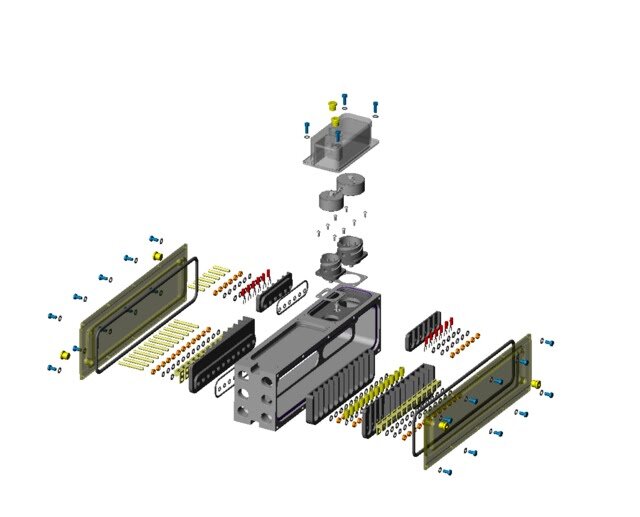

This assembly contained thousands of individual components and hundreds of sub-assemblies, with 95% created by myself in SolidWorks.

Mid-plane Cross-select to show internal components

Not only CAD creation, but in-charge of overall component Integration

Worked with all engineering departments, both Electrical and Mechanical to qualify designs and make sure changes still worked within the whole project. Communicated to manufacturing engineering staff for continuity of project completion, component integration, and compatibility.

Simple Rendering

Helping outside organizations understand design intent.

Sales and Maintenance Graphics

Proved rendering and line graphics to assist Sales and Maintenance staff.

Pushing the limits of Design

Reported progress to project managers and created project schedules; conduct meetings with service staff, chief engineering staff.

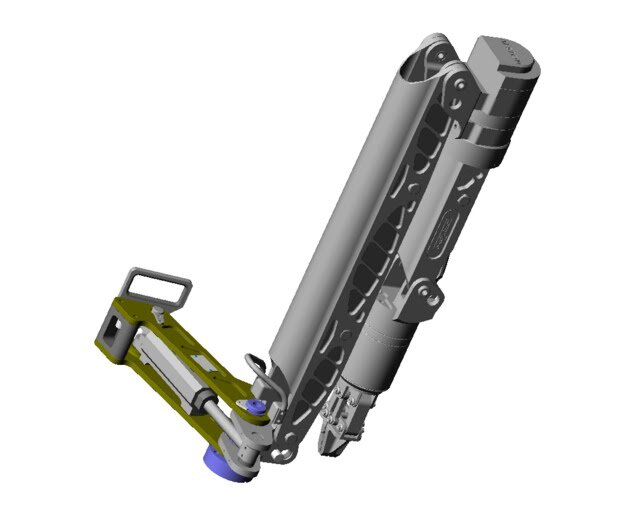

Motion Studies

This project had many dynamic and moving assemblies which had the potential for collisions. All range of motion studies were done before the first parts were made.

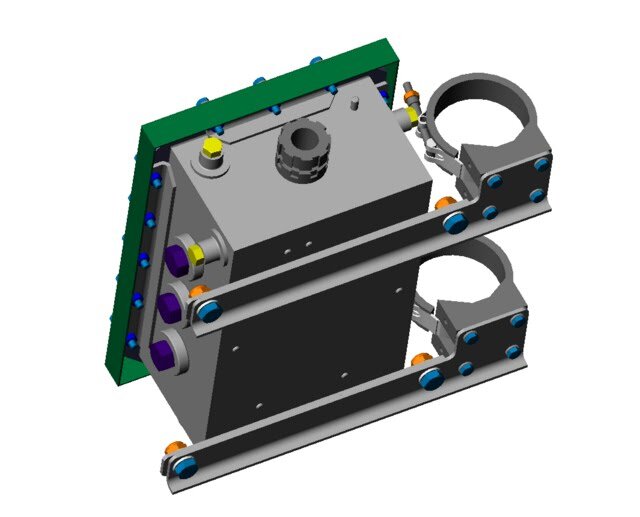

Helping to Visualize Uncommon Designs

Many systems were on ‘The Bleeding Edge’ of technology, 3D design allowed all parties involve to understand design intent.

At 6,000 meters depth all components had to withstand 8,705 psi of sea water

First Prototype of functional system

Bring CAD files to life for harsh environments.

Designed pilot control console

Enclosed eight computers: two network systems, four proprietary hand- controller pucks and two LCD touchscreen interfaces. Fiber-optic communication to the ROV 6,000 meters below

Hands on Prototyping

I had the opportunity to fully assemble the first control console by myself to proof design, create assembly and service documentation.

Understanding manufacturing and serviceability

Fully documented assembly and service procedures.