Large Format CNC Machine

With the K250 Submersible contract I needed a large CNC machine

Completely Designed in Solidworks

Design was fully tested using finite analysis and motion studies in SolidWorks before the first part was made.

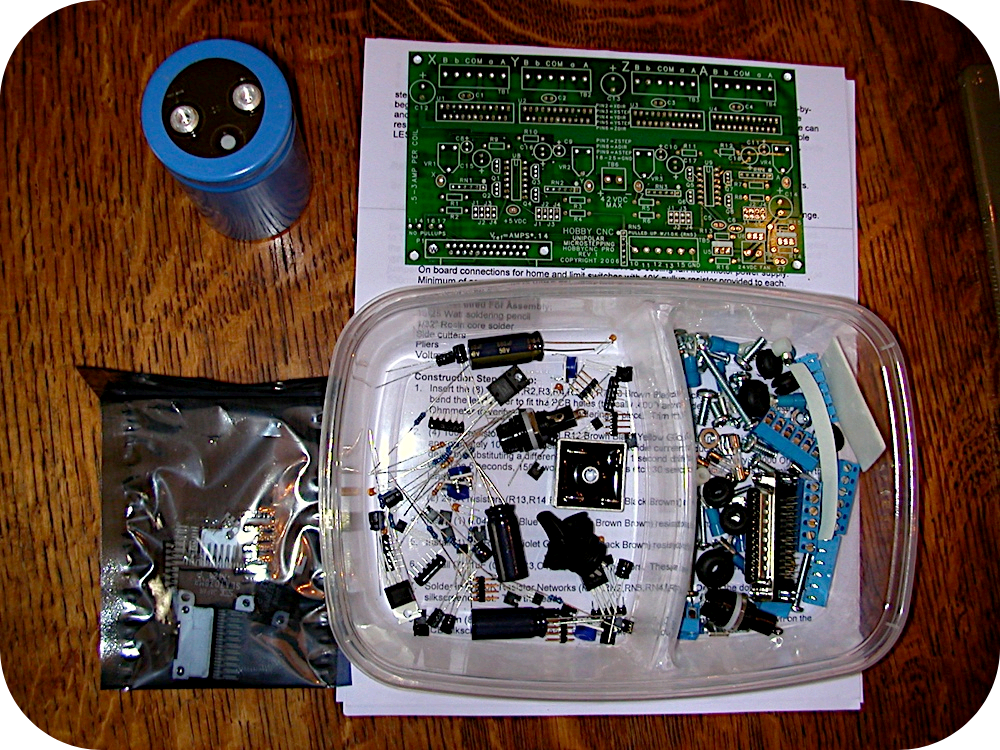

Most of the electronic components were procured individually and bare PCB boards.

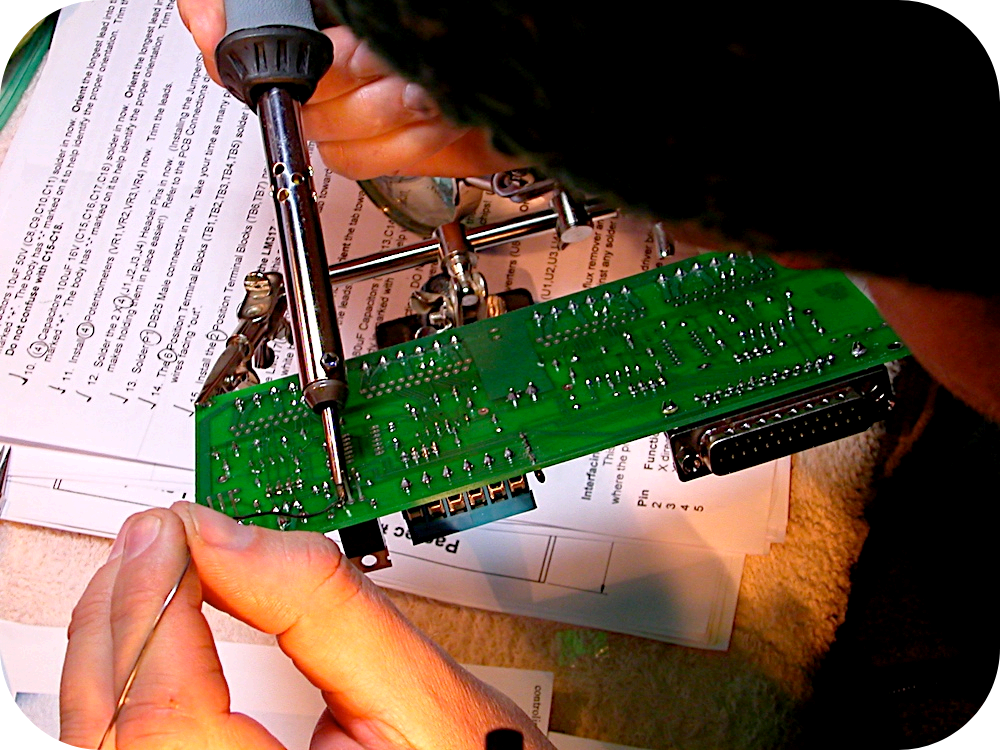

All the electronic components had to be soldiered to these bare PCB boards. I really enjoy these projects.

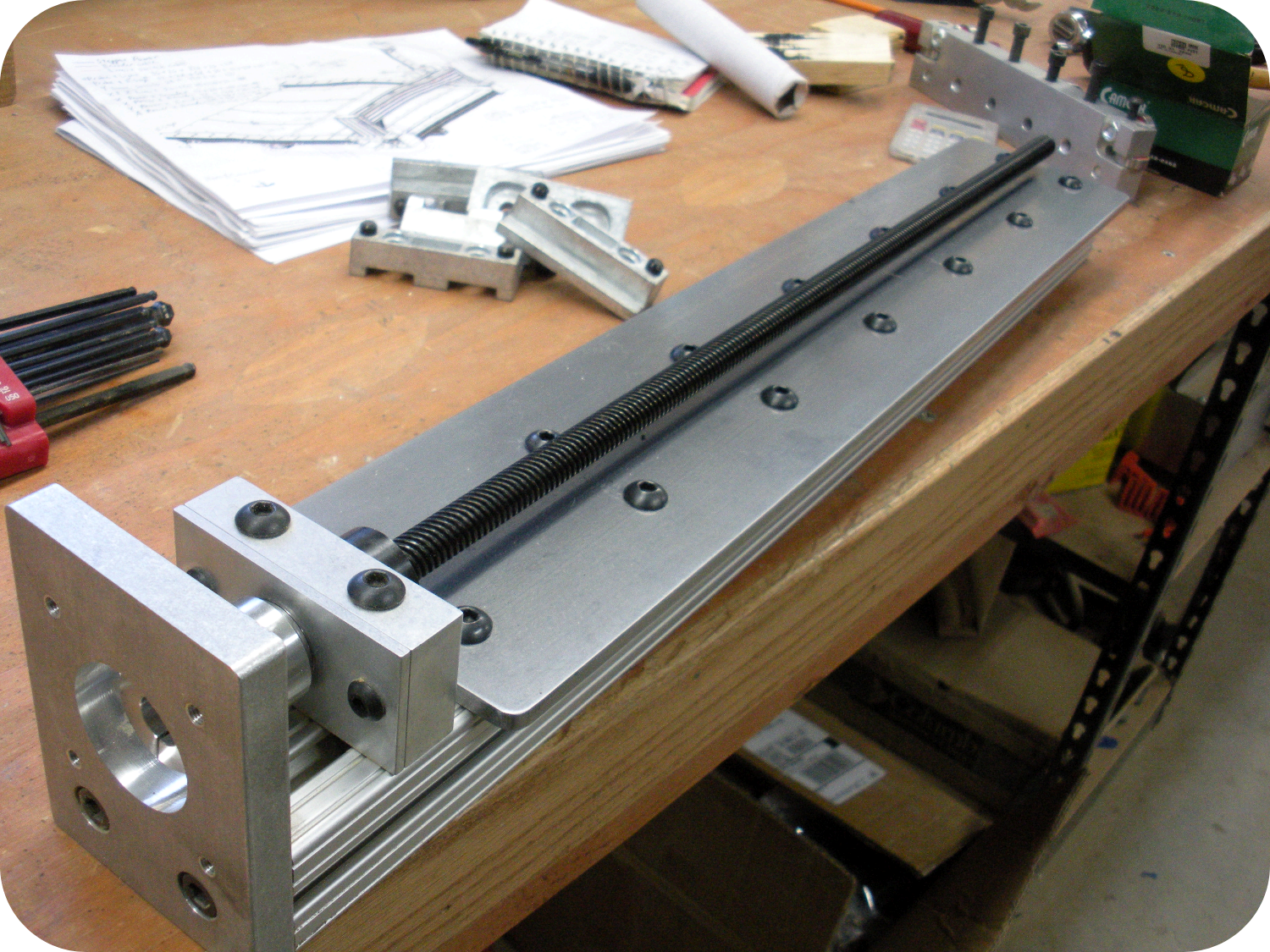

Some machined parts were purchased as part of the 8020 extruded profiles.

While many were CNC machined by myself using HAAS CNC mills at an University.

Some were machined on my first small CNC machine. Regardless of which machine I used, I did all the tool-path programming from Solidworks models.

Fully assembled and really to cut parts. There was zero waste, all machined parts fit perfectly together.

Feed through design

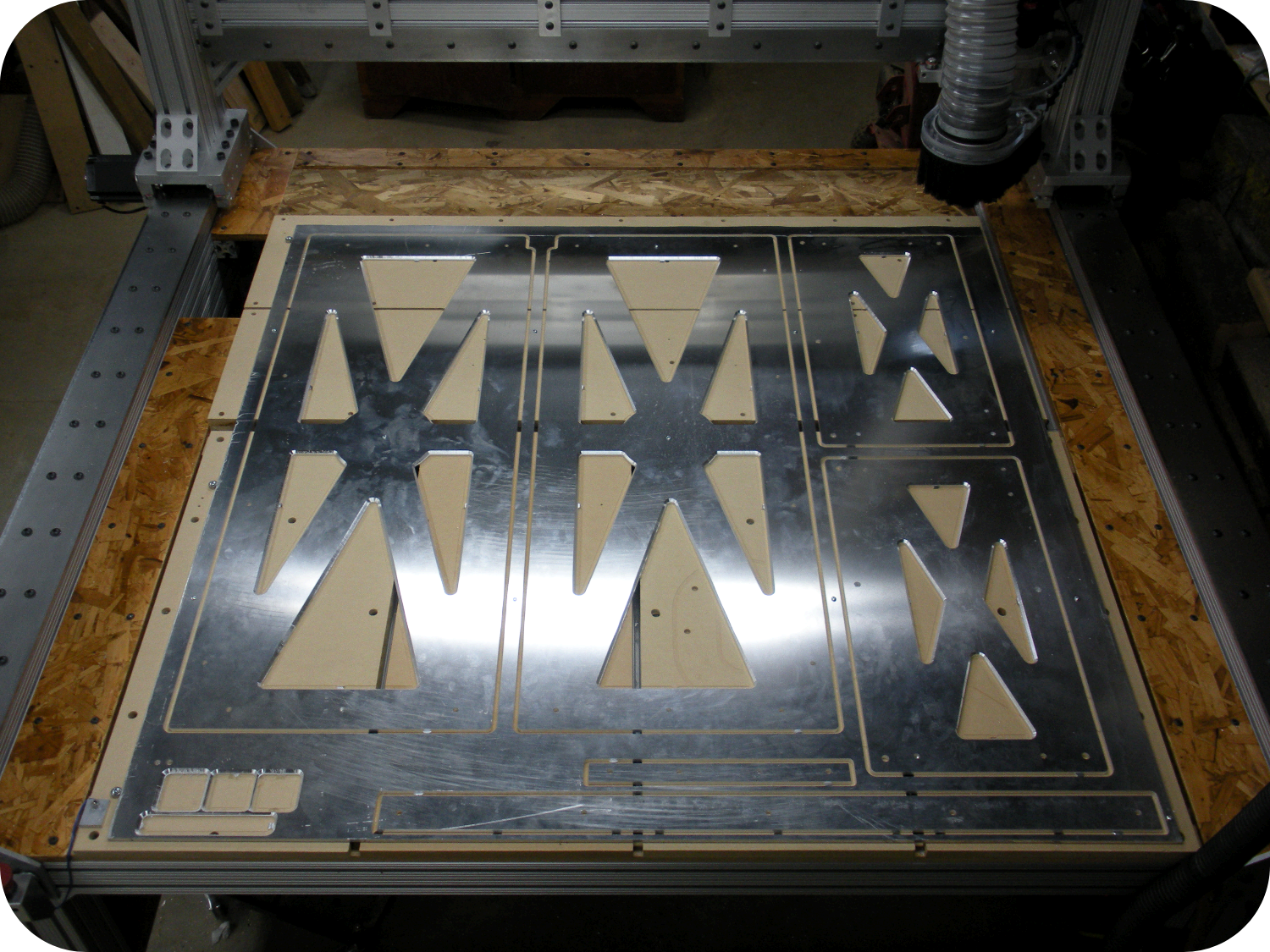

Much of the raw materials which include wood, MDF, UHMW, acrylic and Delrin plastic, aluminum, mild and hardened/stainless steel had to be machined from 8 ft x 4 ft sheets. I designed the system to be able to machine 54 inch x 54 inch x 8 inch working envelope. Large stainless index pins kept the continuous sheets aligned with high accuracy.

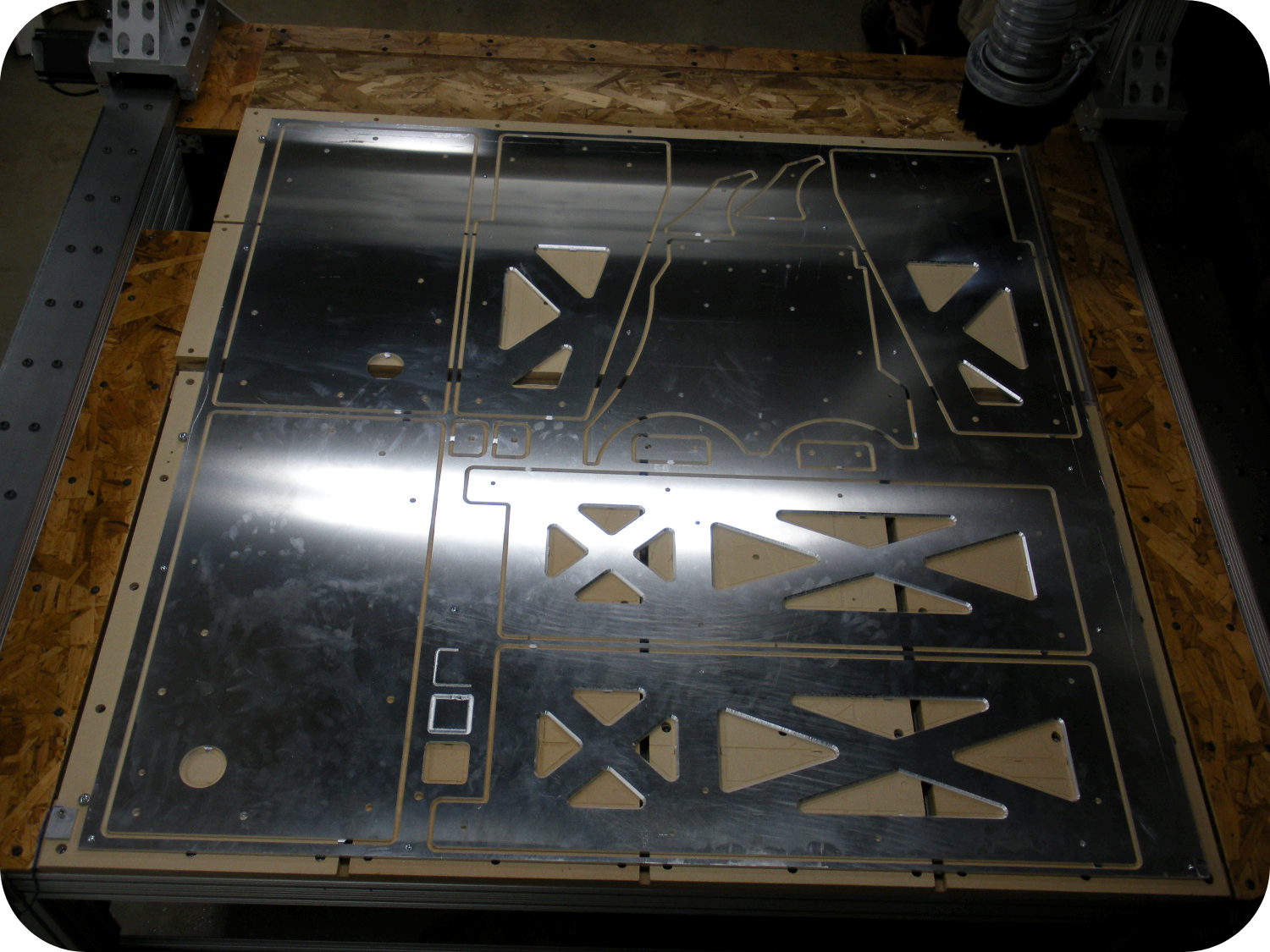

I cut the first 8 x 4 foot plate into two 4 x 4 foot sheets.

This shows the first sheet completed, I tried to use every inch.

I manually did all the nesting, the process of laying out cutting patterns to minimize the raw material waste.

The first set of machined parts laid out, for scale the vertical dimension is approxmently 9 feet long.

This was a sheet of UHMW (ultra high molecular weight polyethylene) plastic sheet 1/2 inch thick. This rugged material was selected for many exterior components.

This set of components machined were used as part of the basket assemble that held the SCUBA diver support air hoses.

8 Foot Long parts, not problem

More CNC machined components can be found on the K250 Submarine page.